Companies Improve their Supply Chains with Artificial Intelligence

- by 7wData

Many large enterprises use one form or another of a Supply chain application to help manage their supply chains. Supply chain vendors have been touting their investments in artificial intelligence (AI) for the last several years. In the course of updating our annual research on the supply chain planning market, I talked to executives across the industry. Alex Pradhan, Product Strategy Leader John Galt Solutions, told me that “all planning vendors have bold marketing around AI.” But the trick is to find suppliers with “field-proven AI/ML algorithms” that “have been delivered at scale.”

Further, while artificial intelligence helps solve certain types of problems, Jay Muelhoefer – the chief marketing officer at Kinaxis pointed out – optimization and heuristics work better for other types of planning problems. This article, which is focused on the different types of artificial intelligence used and the types of problems they are solving, is aimed at helping practitioners cut through the hype.

Let’s start with a definition: any device that can perceive its environment and takes actions that maximize its chance of success at some goal is engaged in some form of artificial intelligence (AI). AI can refer to several different types of math. But, in the supply chain realm, machine learning (ML) is where most of the activity surrounding artificial intelligence has been focused.

It is also worth pointing out, that based on this definition, not all forms of machine learning are particularly complicated. Planning applications don’t work well if the master data they rely on is not accurate; this is known as the “garbage in, garbage out” problem. Artificial intelligence is beginning to be used to update the data. Lead times, for example, are a critical form of master data for planning purposes. Having an agent detect how long it takes to ship from a supplier site to a manufacturing facility, and then doing a running calculation on how the average lead time is changing, is trivial math. The agent technology is much more complicated than the math. Relying on humans to update this data has not worked at all well; people just don’t want to do it.

But sometimes fixing the bad data problem is complicated. In process industries the supply chain models used for optimization are much more complex than those used in other industries. The processing units in an oil refinery, for example, operate at high temperature and high pressure. These constraints need to be understood. So, models for heavy process industries often include first principle parameters. First principles reflect physical laws such as mass balance, energy balance, heat transfer relations, and reaction kinetics. The first principles are important to understand yields, as well as the energy requirements for running the equipment.

AspenTech has developed in a process simulator which is tuned with real plant operating data. During development, the models automatically perform thousands of permutations and perturbations of the first principles model to create a large data set to which AI algorithms applied. The AspenTech models combine the classic first principles approach with the modern pure data-driven approach. Starting with a first principles model, according to AspenTech, improves accuracy significantly. They tell me, the model with either a first principles or pure data plus AI, the model accuracy would be in the 90-97% range. But hybrid models that combine first principles, data-driven models, and AI, they have 99+% accuracy.

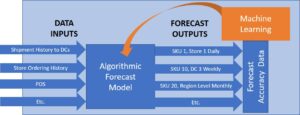

A supply chain planning model learns when the planning application takes an output, like a forecast, observes the accuracy of the output, and then updates its own model so that better outputs will occur in the future.

When you look at machine learning this way, artificial intelligence for supply chain planning is nothing new. Machine learning has been used to improve demand forecasting since the early 2000s.

[Social9_Share class=”s9-widget-wrapper”]

Upcoming Events

From Text to Value: Pairing Text Analytics and Generative AI

21 May 2024

5 PM CET – 6 PM CET

Read More